Basic 2-axis Turning package

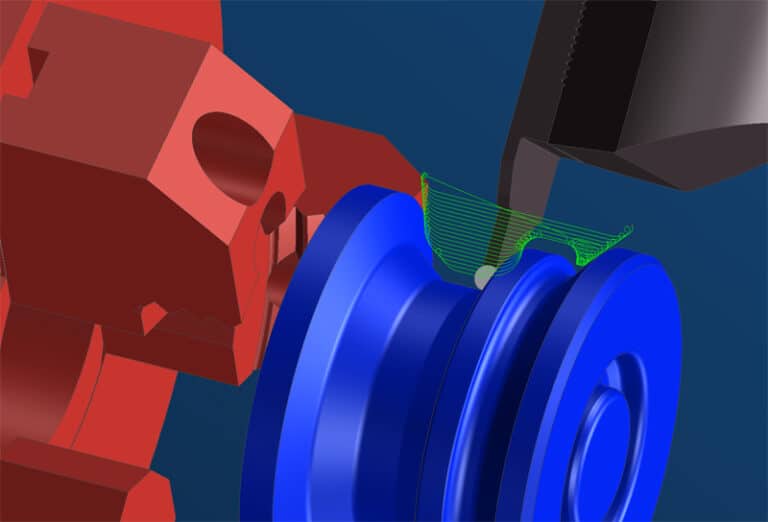

Gibbscam go Turn

The basic package for turning has complete CAD for quick creation of 2D geometries and import of drawings via DXF, DWG and IGES. The CAD module includes drawing functions for all types of geometries. The turning toolpaths offered are state-of-the-art and include many highly productive methods for roughing and finishing, grooving, threading, drilling – all with full restmaterial support.

EASY

You will learn the basics of the GibbsCAM GO Turn package in one to two days.

POWERFUL

The very latest technologies are included already in the basic package. The turning methods include both VoluTurn dynamic turning and Sandvik Prime Turning. This ensures your competitiveness, provides both short run times on the machine and extended tool life.

Powerfully Simple. Simply Powerful.

Machinist friendly

GibbsCAM is widely known as easy to learn and easy to use. The user interface is fully graphical without levels of submenus to scroll through. This makes learning time short and productivity high – in short, fewer clicks to get the job done!

Associative

Everything is associative. If the drawing changes, the programming is updated. When programming, the user can easily save his "own processes". This provides great time savings as tool selection, speeds and method can be saved and reused on other parts.

Smart

"Auto clearance" and "Material only" greatly simplify lathe programming. GibbsCAM constantly keeps track of remaining material and optimizes air moves between operations. This results in smart NC programs and short cycletime in the machine.

GET A DEMONSTRATION

Contact us, and request a demonstration of GibbsCAM.

We can present GibbsCAM over the web, or visit you.

TRY GIBBSCAM

You can also request a 30 day free GibbsCAM testdrive. We’ll get you started and supply a post or G code for your machine.

MILLTURN LATHES

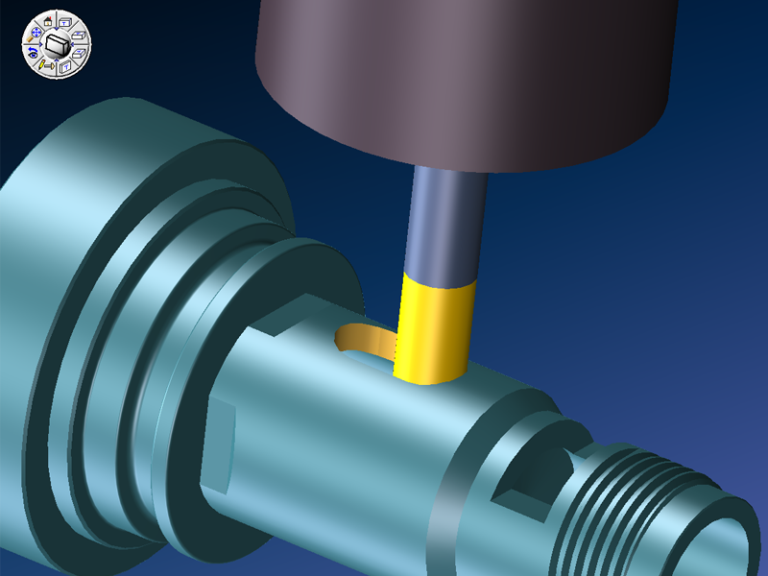

GIBBSCAM GO MILLTURN

The GO MillTurn package is intended for lathes with live tooling and, where applicable, both C, Y, and B-axis. In short, one could say the Millturn package combines the GibbsCAM milling package with turning. In the Millturn package there is also support for "utility" operations such as loaders, steady rests, parts catcher, tail stock, bar feeders, etc.

The Sky is the Limit

Depending on the configuration, GibbsCAM GO MillTurn can program simple 2.5D parts or complex 3D freeform parts using the machine's B, Y or C axis. Which axis is used can be chosen as needed, while programming. Simultaneous 4- and 5-axis milling can also be added to the MillTurn package. There is really no limit.

Prime Turning, Y-axis turning, Broaching, Elliptical turning...

The kinematics engine (UKM) in GibbsCAM is almost limitless in what it can achieve. Thanks to UKM, GibbsCAM supports a variety of advanced and highly efficient turning methods. As an example, both Sandvik PrimeTurning and Freeturn (Y-axis turning) is supported. These represent the latest in turning technology and significantly increase productivity in many applications. GibbsCAM Millturn also supports Elliptical turning, Eccentric turning and Interpolation turning / Orbit turning as well as unique functions for Broaching (linear and rotary).

One CAM Software.

All Your CNC Machines.

GibbsCAM has what it takes to program all your machines, from simple 2-axis to advanced machines with 20 axis.

The world's largest MTM postlibrary with +1500 post processors.

Below are some of the supported machines:

Okuma LT / LB / MacTurn / Multus, Mazak Integrex / QuickTurn / Nexus / Multiplex / HyperQuadrex, Moriseiki MT / NT, DMG Mori, Miyano BNC / BNE / ABX, Hitachi Seiki SuperHicell, Traub TNL / TNS / TNC, Nakamura WT / WTS / NTJ / NTX, Citizen M20 / 32, SMT CC4200, Index C200 / G300 / ABC / TNX / TNL, Hardinge Conquest, Schaublin 42, Haas TL15/25, Doosan Puma TT / MX / SMX, Star, Citizen, Gildemeister CTX, Beta, Gamma, TT, Tornos Deco-serien (Swiss) ….

MultiTaskMachining

GIBBSCAM MTM

The GibbsCAM MTM module is intended for advanced lathes with multiple spindles and/or multiple toolgroups. In MTM you can machine with multiple tools at the same time over one or more spindles thanks to our "sync-manager". MTM machines are available in a multitude of different configurations, some machines can be considered milling machines with turning functionality and others can be seen as lathes with milling functionality. GibbsCAM MTM supports them all, both turret and swiss style lathes.

Unlimited...

Gibbs MTM has been developed with these complex machines in focus. It therefore supports an unlimited number of spindles and toolgroups, any axis configuration and can be adapted to all CNC control systems.

Each machine is a individual

Each machine application in GibbsCAM is customized exactly for the specific machine. Each programming solution offers control over exactly the devices that your machine is equipped with (steady rest, robot loader, bar feeder, tailstock, etc.). All machine adaptations can be completed with Machine Simulation which helps the user detect collisions, overtravel, incorrect tool lengths, etc.