BASIC 2.5D MILLING PACKAGE

GIBBSCAM GO MILL

Already in GibbsCAM's basic package for milling, you will find advanced functions such as 2.5D taper milling, VoluMill dynamic milling, spiral milling/thread milling, the ability to describe your own stock material shapes, high-speed milling with soft toolpaths, engraving of all imaginable fonts - and much more.

Support for coordinate systems and machining planes to support the machine's 4th/5th axis is included. Cylindrical milling (RotaryMill and RadialMill) is also offered for machines with a simultaneously rotating fourth axis (A,B,C).

Drawings can be created directly in GibbsCAM's built-in CAD part or imported from other CAD programs. GibbsCAM is available in Swedish and Finnish for faster learning.

Powerfully Simple. Simply Powerful.

Machinist friendly

GibbsCAM is widely known as easy to learn and easy to use. The user interface is fully graphical without levels of submenus to scroll through. This makes learning time short and productivity high – in short, fewer clicks to get the job done!

Associative

Everything is associative. If the drawing changes, the programming is updated. When programming, the user can easily save his "own processes". This provides great time savings as tool selection, speeds and method can be saved and reused on other parts.

Reliable

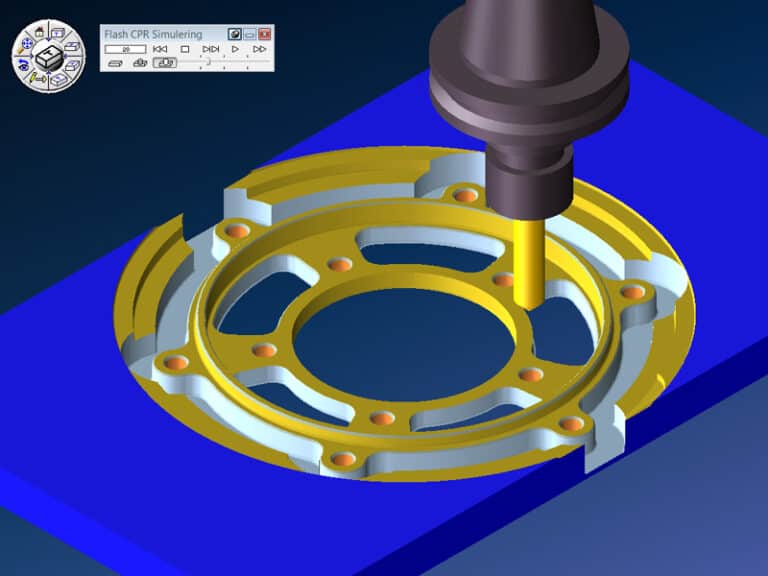

Simulate everything, interactively in 3D. Step by step, fast forward, compare simulation with drawing etc. Reveal mistakes on-screen so they don't occur in the machine. Quality posts guarantee what happens in simulation also happens on the machine.

GET A DEMONSTRATION

Contact us, and request a demonstration of GibbsCAM.

We can present GibbsCAM over the web, or visit you.

TRY GIBBSCAM

You can also request a 30 day free GibbsCAM testdrive. We’ll get you started and supply a post or G code for your machine.

Solids based 2.5D Milling

GIBBSCAM GO SOLID MILL

The “GO Solid Mill” package contains all the functions of the “GO Mill” package, plus:

Solid modeling so you can create, edit and import solid models and build your own fixtures and stock models. Smart 2.5D toolpaths that can be placed directly on solid and surface models. Support for positioning 4th/5th axis and rotary milling is built-in. This module includes our smart “Profile Expert” which automatically tracks contours, holes, pockets and islands for milling as well as AFR (Automatic Feature Recognition) which automatically recognizes hole type and automates hole processing. The module also includes smart assembly tools for fast part setups.

Support for all CAD programs

In all of our solid-based GibbsCAM packages, you can read files from all leading CAD programs. A large number of file formats are supported, including: IGES, PARASOLID, ACIS/SAT, SolidWorks, SolidEdge, PTC/Creo, Catia, Siemens NX, VDA, STEP, Rhino, Autodesk Inventor.

Freeform 3D Milling

GIBBSCAM GO PRO MILL

Freeform machining and freeform 3D CAD

This package offers everything from "GO Solid Mill" plus a variety of advanced 3D milling methods for roughing & finishing, restmaterial milling, milling with constant cusp height, plunge milling and more. In addition, a complete 3D hybrid CAD for the most difficult shapes. Toolpath can be created based directly on solid models, surface models and STL models. Specific functions for mould & die include automatic kernel generation, shrinking, automatic parting line, as well as Boolean operations such as add, subtract and intersect. For those who import surface models, there are unique tools to quickly repair defective surface models and convert them to solids.

The milling functions also support 4th and 5th axis positioning and rotary machining. Five axis simultaneous milling can be added as an option.

A Level that Matches Your Needs

GibbsCAM offers different levels of solids based CAM programming. Start with a lower level, upgrade as your needs change. Some important differences between GibbsCAM GO SOLID Mill and GibbsCAM GO PRO Mill are illustrated below.

FEATURE

IMPORT SOLID AND SURFACE MODELS

EXTRACT GEOMETRY FROM 3D MODEL

ADVANCED SURFACE SELECTION

MACHINE DIRECTLY ON SOLID

FULL RESTMATERIAL SUPPORT

SOLID & SURFACE MODELING (basic)

FREE STOCK AND FIXTURE SHAPE

MODIFY IMPORTED MODEL

SMART “PROFILE EXPERT” FUNCTION

AUTOMATIC HOLE MACHINING (AFR)

VOLUMILL 2D/3D (dynamic milling)

SOLID & SURFACE MODELING (freeform)

MOULD AND DIE FUNCTIONS

ADVANCED 3D TOOLPATHS

PROJECTED TOOLPATHS

CONSTANT CUSP TOOLPATHS

ADAPTIVE ROUGHING

MACHINING ON STL MODELS

GO SOLID MILL

X

X

X

X

X

X

X

X

X

X

X

GO PRO MILL

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Four and five axis milling

GIBBSCAM 5-AXIS

GibbsCAM's 5-axis solutions can be used for both milling machines and for lathes with live tools. The module can create toolpaths for 3, 4, or 5 simultaneous axes. The five-axis module offers a extensive set of advanced milling methods that make material removal more efficient while at the same time giving the opportunity to program those really difficult shapes. This option offers high-end toolpaths such as automatic deburring, turn milling, portmilling, swarfmilling, impeller machining, geodesic machining and much more. A world of possibilities.

Difficult made Easy

The five-axis module includes predefined milling methods for common tasks such as swarfmilling, engraving, five-axis drilling, etc. These simplified machining methods are easy to learn and require very little input from the user.

Advanced Collision Handling

5-axis also offers extremely advanced collision control. The tool, the shank, the holder, the stock, the part model – all objects can be defined as collision objects. Different behaviors can be defined based on how a collision is to be avoided. In one situation the tool must be lifted up, while in another the tool must be tilted away from the detail - the possibilities are extensive.

We recommend the five-axis module to be combined with a complete Machine Simulation model, for the most accurate collision verification and highest safety.

Multiblade & Portfräsning

gibbscam MultiBlade

The GibbsCAM MultiBlade option is designed with a single purpose; - to simplify programming of impellers and blade parts (turbines, propellers and the like). MultiBlade offers automatic recognition of impeller blades and splitters, smart trimming of toolpaths and includes both roughing and finishing strategies – especially intended for blade designs.

gibbscam PORTMILLING

For those who work with port milling, machining cylinder heads and similar tubes, there is a special option that simplifies and streamlines programming of these complex internal shapes. The module automatically detects the center curve of the port or tube so that entry and exit movements of the tool are created without collision.

One CAM Software.

All Your CNC Machines.

GibbsCAM has what it takes to program all your machines, from simple 2-axis to advanced machines with 20 axis.

MULTIPART Programming

GIBBSCAM TMS

The TMS (Tombstone Management System) option simplifies programming dramatically for those who often program multiple parts on different tombstone sides in, for example, horizontal milling machines. TMS provides up to 80% time savings compared to traditional CAM programming.

The idea of TMS is simple

In TMS, the first part, and all the rotations for that part, are programmed first. Then, conditions for part repeats are set in TMS, which then automatically takes care of the zero point setups and WFO position input in the machine (eg G10 P1, P2). TMS automatically creates short and smart NC code with subprograms. TMS can be added to any solids based GibbsCAM package. After programming, GibbsCAM's machine simulation will simulate and display all repeats, machining sequence and clearance moves - everything can be verified quickly and precisely.

If you program tombstones and multiple part setups, you should take a closer look at TMS.